VINYL IS ALIVE! CONTINUED

| J.R. Ferguson has been with MusIcol for a long time and has become quite proficient in the manufacture of vinyl records. J.R.s interview |

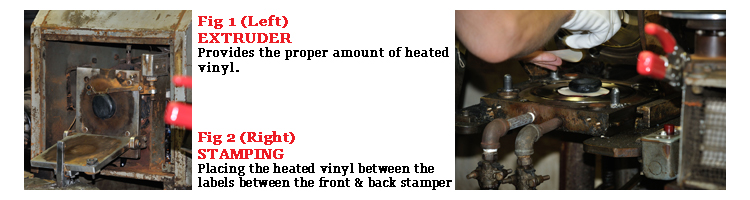

| As shown above, you see a 45rpm record being trimmed after it is removed from the stamping machine. Small pellets of vinyl are melted and pressed through an extruder as shown in Fig 1 and 2. This ball of plastic is placed onto the stamper between the labels and then “abracadabra”, the machine produces a finished product which is then stacked, cooled, placed in a sleeve and a jacket. J.R. will explain this process more in his interview. We also illustrate this process in “The Musicol Tour Video” CLICK HERE! |

|

|